Services

Kolibri Tech provides end-to-end solutions for your most critical applications. Let us be your resource to determine which manufacturing process is right for your project

01.

Sheet matel fabrication

Kolibri Tech is a leading sheet metal processing manufacturer specializing in high-precision metal component fabrication. In the past 15 years, with a blend of manual expertise and advanced technology, we met diverse fabrication needs with accuracy and skill. We delivered tailored solutions for industries including home appliance,electronics, aerospace and automotive etc.

02.

CNC Precision machining

From quotation to production and quality control, Kolibri Tech have built our entire manufacturing process around high-quality and fast service to help transform ideas from CAD designs into products. We will work with you to verify and improve your product ideas, functional testing and engineering verification. Our CNC machining center is designed for fast prototypes and small batch production. We can either produce complex prototypes or small batch production of precision machined parts, including various metals and plastics, and various surface treatments.

03.

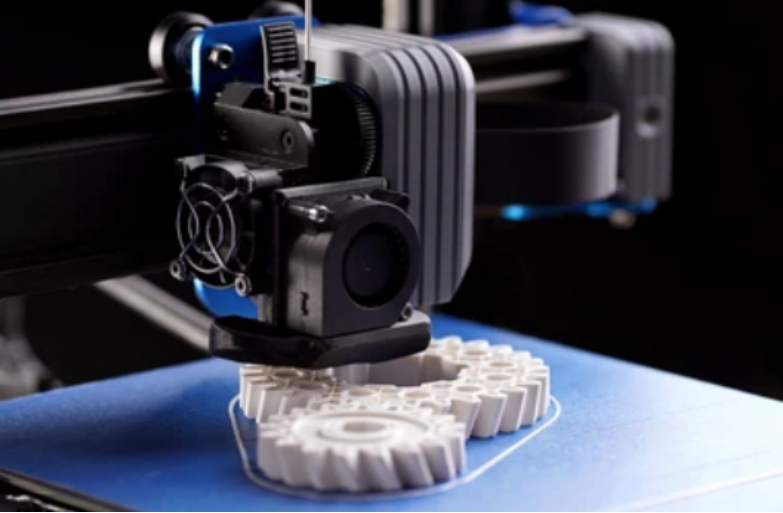

3D Printing

From rapid prototypes to end-use production parts, Kolibri Tech delivers high-performance 3D printing solutions built for speed, precision, and scalability. We’re a dedicated partner to engineers, designers, and product teams. Our deep industry expertise, responsive support, and proven track record ensure you have the guidance and reliability needed at every stage of development. From initial design reviews to production-ready parts, we help you navigate complexity with confidence and bring your products to market faster.We’re your trusted partner for advanced additive manufacturing

04.

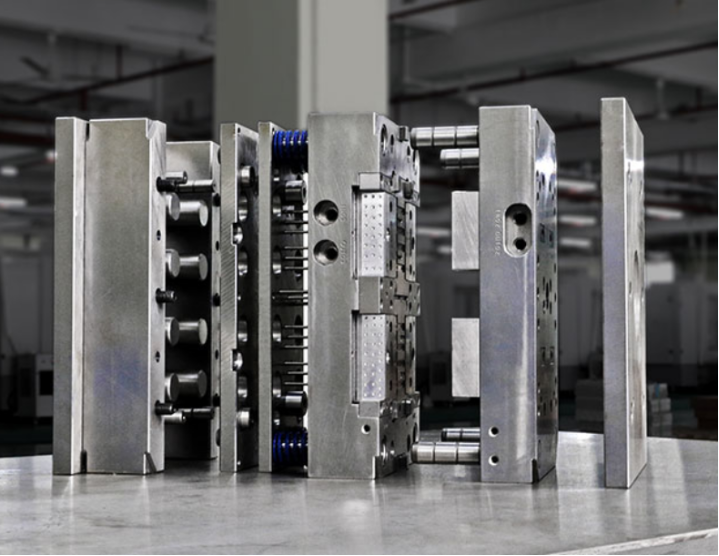

Injection Molding

Injection molding is a manufacturing process that consists of filling a metal mold cavity with liquid plastic resin, which then cools and forms a plastic part.It's most often used for the manufacturing plastic parts at scale due to its low material waste and low cost per part. It’s an ideal manufacturing process for industries like medical devices, consumer products, and automotive.Our plastic injection molding process produces custom prototypes and end-use production parts. We use aluminum or stainless steel molds that offer cost-efficient tooling and accelerated manufacturing cycles

Why Partner With Us?

Global Reach: Servicing 26+ countries with 24/7 emergency order support

Tech-Driven: AI-powered predictive design and manufacturing

Fast Delivery: 98% on-time completion for urgent orders

Cost efficiency:30% lower production costs vs. Western suppliers

Trust Remains, Reliability Sustains.

We are helping businesses to manufacture with the best quality and precision.We strive to offer our customers creative ways to make their products on the world's most advanced technology. Let us be your resource to determine which manufacturing process is right for your project.